PRO-TRACE HF-CCS PE30/PE45

SKU-7441 | SKU-7444

TECHNICAL DOCUMENTS

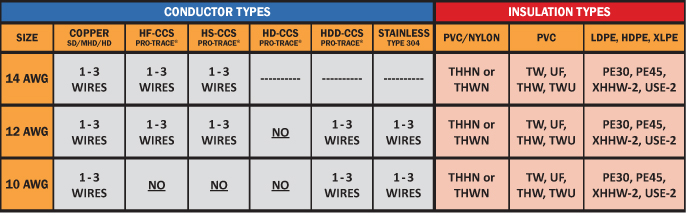

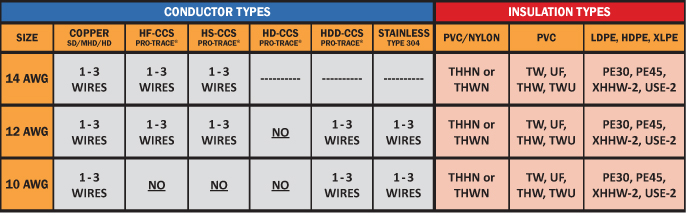

UNDERSTANDING YOUR TRACER WIRE SELECTION

APPLICATIONS & INFORMATION

PRO-TRACE HF-CCS PE30/PE45 tracer wire is designed to have the flexibility, memory, and feel of copper. It also has a 43% higher break-load , minimizing damage during installation and while in service. This product is best suited for open-trench applications. Equal in signal tracing performance, it simply outperforms copper tracer wire and significantly reduces material costs.

- Designed for Open-Cut, Plow-In, and Blow-In Applications.

- Flexibility, Memory, and Feel of Copper.

- 43% Higher Break Load than Copper.

- Corrosion Resistant Properties of Copper

- Tracer Wire Performance Equal to Copper.

- 30/45 Mil, High-Density, HMWPE Insulation (HDPE), and Direct Burial Rated.

- Significantly Lower in Cost with Great Price Stability.

- User-Friendly and Virtually No “Recoil”.

STANDARDS & REFERENCES

-

ASTM B910 / B190M: Standard Specification for Annealed Copper-Clad Steel Wire.

- ASTM B170: Standard Specification for Oxygen-Free Electrolytic Copper.

- ASTM D1248: Standard Standard Specification for Polyethylene Plastics Extrusion Materials For Wire and Cable

TRACER WIRE CONSTRUCTION

PRO-TRACE HF-CCS PE30/PE45 is a flexible, copper-clad steel tracer wire. A low carbon steel core, metallurgically bonded with a copper cladding, that is uniform and continuous, creating a bi-metal conductor that acts as one and is corrosion resistant. Special annealing processes are performed during the cladding process giving HF-CCS the flexibility and feel of copper, but 43% higher in strength which means less breaks then copper tracer wire.

PRO-TRACE HF-CCS PE30/45 uses a 30/45 mil, high-density, high molecular weight polyethylene (HDPE) insulation. HDPE provides an excellent balance of surface smoothness, processing ease and electrical consistency. HDPE provides superior strength against underground elements that help prevent accidental breaks caused buy rocks in shifting soil conditions.

TABLE 1: CONDUCTOR PROPERTIES (PHYSICAL, MECHANICAL AND ELECTRICAL)

TABLE 2: INSULATION PROPERTIES (PHYSICAL, MECHANICAL AND ELECTRICAL)

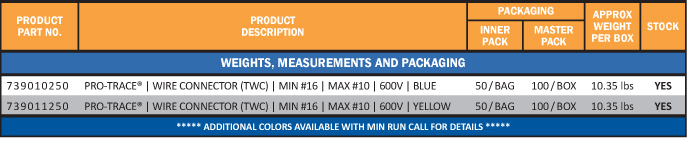

WEIGHTS, MEASUREMENTS, AND PACKAGING

SPECIFICATION EXAMPLE (FOR SPECIFYING ENGINEERS)

Tracer wire for open-cut installation shall be a 12 AWG solid, PRO-TRACE HF-CCS PE30/PE45. Conductor shall be annealed, 21% IACS, copper-clad steel, utilizing a AISI 1006 low carbon steel core with minimum break load of 282 lbs or 55,000 psi (required to meet break load, flexbility, and ASTM B910). Conductor shall be extruded with a 30/45 mil, high density, high molecular weight polyethylene (HMW-HDPE) persuant to ASTM D1248. Tracer wire shall be rated for direct burial use at 30 volts and RoHS compliant. Tracer wire shall be PRO-TRACE HF-CCS PE30/PE45 as manufactured by Pro-Line Safety Products.